- HOME

- PRODUCTS

- BLOWN FILM LINE

- MULTI LAYER CO-EXTRUSION HIGH SPEED BLOWN FILM LINE

Products

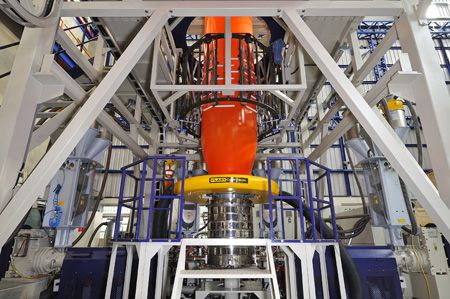

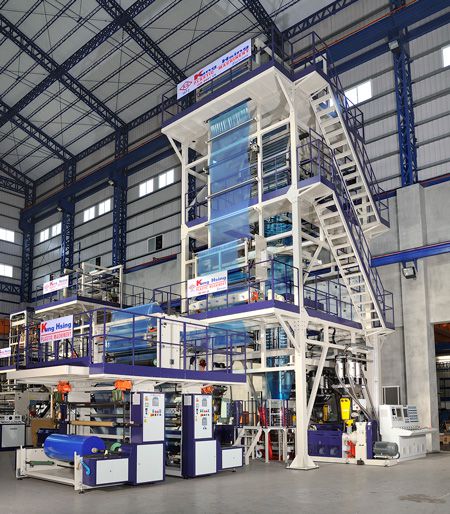

FIVE AND SEVEN-LAYER CO EXTRUSION BLOWN FILM MACHINE

● AUTO THICKNESS PROFILE CONTROL(AUTO AIR RING, GERMANY MADE)

● 360 DEGREES THICKNESS PROFILE MEASUREMENT

WITH OSCILLATING RAIL (GERMANY MADE)

● GAIN IN WEIGHT DOSING UNIT (GERMANY MADE)

● IBC COMPUTER CONTROL SYSTEM (U.S.A MADE)

● HORIZONTAL OSCILLATING TAKE UP UNIT

● BACK TO BACK AUTOMATIC SURFACE TYPE WINDER

- Specification

- Video

- Photograph

- Device

| MODEL | KS-ML-5-50+55+65 | ||||||||||||||||||||

| FEATURE | MATERIAL TO BE USED | LDPE LLPDPE HDPE EVA PP NYLON (CUSTOMRISED, PLEASE ADVISE MATERIAL) | |||||||||||||||||||

| MAX. FILM WIDTH | 1500 mm | ||||||||||||||||||||

| THICKNESS OF FILM | 0.03~0.20 m/m | ||||||||||||||||||||

| MAX. EXTRUSION OUTPUT | 430 kg/hr | ||||||||||||||||||||

| EXTRUDER | SCREW DIA. |

50 mm × 2 55 mm × 2 65 mm × 1 |

|||||||||||||||||||

| SCREW L/D | 30 : 1 | ||||||||||||||||||||

| SCREW / CYLINDER MATERIAL | SACM 645 STEEL WITH HARD WITH NITROGEN TREATMENT, HARDNESS 75 OR OVER | ||||||||||||||||||||

| CYLINDER COOLING |

¼ HP × 2 ½ HP × 11 |

||||||||||||||||||||

| DRIVING MOTOR |

30 HP × 2 40 HP × 2 75 HP x 1 |

||||||||||||||||||||

| HEATER CAPACITY | 95 kw | ||||||||||||||||||||

| DIES (mm) | 350 ø | ||||||||||||||||||||

| TEMPERATURE CONTROL | 29 ZONES | ||||||||||||||||||||

| COOLING EQUIP | 10 HP | ||||||||||||||||||||

| TAKE-UP UNIT | TYPE | FIXED TYPE / OSCILLATING TYPE | |||||||||||||||||||

| PINCH ROLLER (mm) | 165 ø × 1600L | ||||||||||||||||||||

| TAKE-UP MOTOR | 2 HP A.C. MOTOR | ||||||||||||||||||||

| TAKE-UP SPEED (m/min) | 10 ~ 90 | ||||||||||||||||||||

| SUB-PINCH ROLLER (mm) | 140 ø × 1600L | ||||||||||||||||||||

| GUIDE MOTOR | 50 kg/cm | ||||||||||||||||||||

| WINDING UNIT | FWC TYPE | ONE STATION SURFACE WINDER WITH AUTOMATIC BOBBIN CHANGE | |||||||||||||||||||

| EFFECTIVE WIDTH | 1500 mm | ||||||||||||||||||||

| DIA. OF FILM WOUND-UP ROLL | 800 mm | ||||||||||||||||||||

| WINDER MOTOR | 2 HP A.C. MOTOR | ||||||||||||||||||||

| DIMENSION (L×W×H) (M) | 14×10×12 | ||||||||||||||||||||

| OPTIONAL DEVICE |

|

||||||||||||||||||||

5-7 muti-layer co-extrusion will be customerised according to the material to be used. The film specification that going to produce, and application of the film.

KS-ML-5-50+55+65

-

AUTO THICKNESS PROFILE CONTROL (AUTO AIR RING, GERMANY MADE)

-

360 DEGREES THICKNESS PROFILE MEASUREMENT WITH OSCILLATING RAIL (GERMANY MADE)

-

GAIN IN WEIGHT DOSING UNIT (GERMANY MADE)

-

IBC COMPUTER CONTROL SYSTEM (U.S.A. MADE)

-

HORIZONTAL OSCILLATING TAKE UP UNIT

-

BACK TO BACK AUTOMATIC SURFACE TYPE WINDER

KS-ML-5-50+55+65

KS-ML-5-50+55+65

FIVE LAYER CO-EXTRUSION BLOWN FILE LINE EQUIPPED WITH GAIN-IN WEIGHT GRAVIMETRIC BATCH BLENDER, AUTO THICKNESS PROFILE CONTROL, IBC COMPUTER CONTROL SYSTEM

KS-ML-5-50+55+65

KS-ML-5-50+55+65

-

AUTO THICKNESS PROFILE CONTROL (AUTO AIR RING)

-

360 DEGREES THICKNESS PROFILE MEASUREMENT WITH OSCILLATING RAIL (GERMANY MADE)

-

GAIN IN WEIGHT DOSING UNIT (ITALY MADE)

-

IBC COMPUTER CONTROL SYSTEM (U.S.A. MADE)

-

HORIZONTAL OSCILLATING TAKE UP UNIT

-

BACK TO BACK AUTOMATIC SURFACE TYPE WINDER

KS-ML-5-50+55+65

.jpg)

KS-ML-5-50+55+65

FIVE LAYER CO-EXTRUSION BLOWN FILE LINE EQUIPPED WITH GAIN-IN WEIGHT GRAVIMETRIC BATCH BLENDER, AUTO THICKNESS PROFILE CONTROL, IBC COMPUTER CONTROL SYSTEM

.jpg)

KS-ML-5-50+55+65

.jpg)

KS-ML-5-50+55+65

.jpg)

KS-ML50+55+65 - K show

.jpg)

KS-ML50+55+65 - K show

.jpg)

ML5-50+55+65 five layer

ML5-65+55+65 five layer